There are small amounts of sugar in all whiskies. Scottish whiskies have some sugars dissolved from the oak cask and often some from optional caramel colouring (E150a). Total amount of sugars is quite low, usually well below 1 g/l, but in certain cases it is quite possible to reach a few grams per liter. The sweet aromas of whisky matured in refill bourbon or new oak casks mostly come from sweet aromatic vanillin and fruity esters, not from the sugars. However, sugars can have a significant role in the case of casks previously used for sweet wine or sweetened spirit.

There are small amounts of sugar in all whiskies. Scottish whiskies have some sugars dissolved from the oak cask and often some from optional caramel colouring (E150a). Total amount of sugars is quite low, usually well below 1 g/l, but in certain cases it is quite possible to reach a few grams per liter. The sweet aromas of whisky matured in refill bourbon or new oak casks mostly come from sweet aromatic vanillin and fruity esters, not from the sugars. However, sugars can have a significant role in the case of casks previously used for sweet wine or sweetened spirit. |

| Typical composition of a liquid E150a colouring |

|

| Caramel content of various whiskies (Boscolo et al 2002) |

Another source of sugars in whisky is wood. Oak is composed of three main macromolecules; cellulose is a long-chain D-glucose-fiber. Hemicellulose is a mesh-like branched chain of 5-carbon sugars (xylose, arabinose, galactose, ribose, rhamnose) and glucose. Lignin is a complex matrix of polypropane and polyphenols. Cellulose breaks down very slowly in alcohol-water solution extracting very small amounts of glucose to whisky. Most sugars extracted from the cask come from hemicellulose, hence most of them are 5-carbon sugars. Arabinose, xylose and rhamnose taste about half as sweet as glucose, where as fructose is almost twice as sweet compared to glucose.

About 100 mg/l of solids (including sugars) is extracted from new charred oak casks during the first year of bourbon maturation and after 1-3 years typically significantly less and only as little as 4 mg/l/year extraction has been reported from old refill casks used for example for cognac (or Scotch) maturation. A toasted cask extracts considerably more sugars compared to a charred cask, but typically about 150-250 mg/l/year is reached for the first year(s) of maturation. For comparison, a 40 years old brandy matured in a toasted oak cask had 2 g/l sugars (averaging 50 mg/l/year), while a 30 years old cognac (probably mostly matured in a refill casks) had only 0.5 g/l (17 mg/l/year).

|

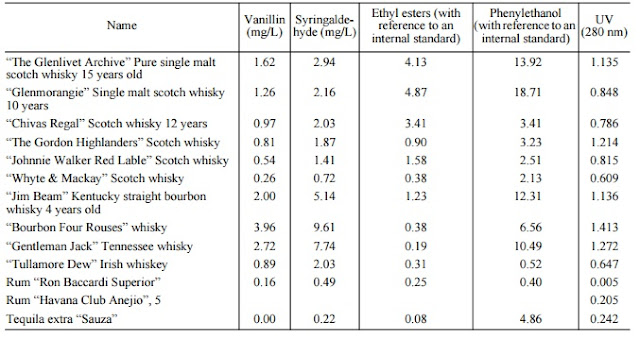

| Analysis of different spirits by GC-MS (Savchuk 2001) Note the high levels of vanillin from new charred casks. |

|

| Venezuelan rum, 40 g/l sugars |

|

| Pedro Ximenez sherry, 470 g/l sugars |

The Scotch whisky industry has preferred sweet sherries for seasoning of their whisky casks from the 19th century and while most modern sherries are quite dry, most ex-sherry whisky casks were used for (or seasoned with) sweet sherries. In the 1800s and the early 1900s sweet(ened) sherries were imported to Britain in shipping casks. Britain was a major importer of sherry and emptied shipping casks were often used for maturation of Scotch whisky. By the late 19th century sherry casks were used extensively in Scotland and the first attempts to rejuvenate or season used casks were made in the 1890s. After the sherry casks were used for Scotch whisky maturation, they were seasoned with sweet sherry or paxarette, sometimes using pressure to soak the wood with the wine. By the early 20th century the use of sherry casks was quite wide spread, for example in the late 1920s a big whisky blender Johnnie Walker matured all of their whiskies in sherry casks or sherry-treated casks.

|

| Aberlour 18yo sugars <2 g/l |

Shipping casks were mostly Spanish coopered lightly toasted American oak (Quercus alba) butts or puncheons (often called bocoyes in Spain). In 1972 Manuel González Gordon stated that "in recent years some Spanish oak has been used, due principally to the difficulties of importing American timber, but its greater density and hardness and lower porosity make it less suitable than the American wood". In the 19th century and the early 20th century they were often used for fermentation prior to shipping. Oak influence was not that detrimental for sherry during fermentation period and the fermentation process was believed to extract some of the excess tannins and bitterness from the wood prior the use in a solera or shipping.

The fermentation phase added plenty of sugars to the oak. For example, a typical 1980s (arguably Spanish oak, but at least Spanish coopered oak) shipping cask previously used for fermentation extracted 2.25 g/l sugars to whisky during only 6 years of maturation (375 mg/l/year). On the other hand an American ammonia-treated cask without a previous fermentation use would extract 770 mg/l (154 mg/l/year) sugars from a fino-seasoned cask and even less 655 mg/l (133g/l/year) from a similar oloroso cask. According to the table below, the previous use as a fermentation cask is very significant in the terms of sugar extraction.

|

| JM Philp 1989 |

|

| Ardbeg Dark Cove 4 g/l sugars |

REFERENCES AND FURTHER READING:

Alañón ME et al. Monosaccharide anhydrides, new markers of toasted oak wood used for ageing wines and distillates. Food Chem 2010;119;505-512

Blanco Gomis D et al. Evolution of sugars in cider brandy aged in oak barrels, a contribution to its characterization. J Agric Food Chem 2003;51;923-926

Boscolo M et al. Spectrophotometric determination of caramel content in spirits aged in oak casks. J AOAC Int 2002;85(3);744-750

Boudet AM et al. Biochemistry and molecular biology of lignification. New Phytol 199;129;203-236

Clyne J et al. The effect of cask charring on Scotch whisky maturation. Int J Food Sci Tech 1993;28;69-81

González Gordon M, Sherry. Cassell Ltd 1972

Haldane FF. Casks; their manufacture and treatment. J Inst Brew 1906;12(7);688-711

Hills, P. Appreciating whisky. Collins 2000

Kansallisarkisto, Helsinki. http://www.arkisto.fi/en/the-national-archives-service/arkistolaitoksen-vaiheet-2

Liebmann AJ & Rosenblatt M. Changes in whisky while maturing. Ind Eng Chem 1943;35(9);994-1002

Martínez Montero C. Estudio de parámetros alternativos como indicatores del envejecimiento y de la calidad del brandy de Jerez. Thesis, Universidad de Cádiz, 2006

Martínez Montero C et al. Sugar contents of brandy de Jerez during aging. J Agric Food Chem 2005;53;1058-1064

Mosedale, JR. Effects of oak wood on the maturation of alcoholic beverages with particular reference to whisky. Forestry 1995; 68; 3; 203-230

Mosedale JR & Puech JL. Wood maturation of distilled beverages. Trends Food Sci Tech 1998;9;95-101

Mosedale JR & Puech JL. Wood maturation of distilled beverages. Trends Food Sci Tech 1998;9;95-101

Piggott JR et al. Effects on scotch whisky composition and flavour of maturation in oak casks with varying histories. Int J Food Sci Tech 1993;28;303-318

Piggott, JR et al(ed). The Science and technology of whiskies. Longman 1989

Piggott, JR et al(ed). The Science and technology of whiskies. Longman 1989

Read J. Sherry and the sherry bodegas. Sotheby's 1988

Savchuk SA et al. Application of Chromatography and Spectometry to the Authentication of Alcoholic Beverages. J Anal Chem 2001;56(3);246-264

Tolman LM & Trescot TC. A study of the methods for the determination of esters, aldehydes and furfural in whisky. J Am Chem Soc 1906;28(11);1619-1630

Tsai PJ et al. Interactive role of color and antioxidant capacity in caramels. Food Res Int 2009;42;380-386

Valaer P & Frazier WH. Changes in whisky stored for four years. Ind Eng Chem 1936;Jan;92-105

Valaer P. Scotch whisky. Ind Eng Chem 1940;32(7);935-943

Valaer P. Foreign and domestic Rum. Ind Eng Chem 1937;Sep;988-1001

Williams JF. Rapid determination of alcohol in distilled spirits and of color in whisky. Ind Eng Chem 1926;Aug;841-843

Savchuk SA et al. Application of Chromatography and Spectometry to the Authentication of Alcoholic Beverages. J Anal Chem 2001;56(3);246-264

Tolman LM & Trescot TC. A study of the methods for the determination of esters, aldehydes and furfural in whisky. J Am Chem Soc 1906;28(11);1619-1630

Tsai PJ et al. Interactive role of color and antioxidant capacity in caramels. Food Res Int 2009;42;380-386

Valaer P & Frazier WH. Changes in whisky stored for four years. Ind Eng Chem 1936;Jan;92-105

Valaer P. Scotch whisky. Ind Eng Chem 1940;32(7);935-943

Valaer P. Foreign and domestic Rum. Ind Eng Chem 1937;Sep;988-1001

Williams JF. Rapid determination of alcohol in distilled spirits and of color in whisky. Ind Eng Chem 1926;Aug;841-843

this is the article i would have wanted to write myself, in a few years, after much research! You just gave me a huge boost in this effort! Do you mind if i refer to your blog ?

ReplyDeleteYou know I won't mind. Go on, enlighten us ;)

DeleteHi. Couldn't find any other way to contact You, so decided to post a comment to the newest post in Your blog. First of all - huge thanks for Your great articles. I'm a whisky making enthusiast and I found a lot of interesting and valuable technological details.

DeleteSo, I have 2 questions:

1. In the "Peat" article You published a table. The third column is named "MIDDLE CUT ABV". Should the figures be understood as a final ABV of newly made whisky right after the second distillation or as a "body" cut point where a specific figure means abv of a distillate in a flow running out of condenser in transition to tails?

2. There is one more question on which I can't find almost any information. I've read that a whisky mash is always made of a blend of different malts. So, like in beer, there is always a base malt with addition of special malts. Do You have any information on malt blending and use of special malts. What special malts are used - cara, melanoid, munich etc.? What percentages of them are common for whisky mash blends?

Beforehand grateful for the answer.

With great respect, Dmitry.

p.s. my email is jazzminos(dog)google-dot-com.

1. The middle cut refers to the ABV of the spirit cut. The bigger abv is the "end of heads and start of cut" and the lower abv is the "end of cut and start of feints".

Delete2. I never heard of a malt mix for whisky (apart from some rare experiments). Scotch malt whisky is made practically always from distilling malt, which is very pale malt (for high alcohol yield). Some of it is peated, but the aim is to keep that pale, too. Compared to brewers, the distillers prefer smaller grain (more enzymes) and low protein. http://whiskyscience.blogspot.fi/2015/03/scottish-whisky-mash-bill.html

Huge thanks for Your reply. The information provided is very helpful.

DeleteConsidering malt mixing everything is clear. I've made several mashes with pilsner malt. I also make experiments with belgian Castle Malting Whisky malt (30-35 ppm phenols) and Whisky Light (5-10 ppm phenols). These peated malts can be purchased here. Results seem to be almost authentic. Analysis for main congeners can be found here https://yadi.sk/i/c5jL4fLA3DKMvp

Considering the first question. The lower abv ("end of cut and start of feints") is quite clear. But the higher abv ("end of heads and start of cut") is somewhat uncelear. I can hardly understand the start of middle cut at 70 abv and even at 68 abv. In my own distillation practice with a simple direct-flow condenser, heads end at 80-79 abv. I usually take heads about 5% of low-wines total volume. One thing to be mentioned - in home distillations we always aim to get heads at a very low distillation speed (as low as 100 ml per hour) to get heads "sharper". So, my assumptions are:

1. The construction of traditional pot stills provides extremely low reflux, so the spirit strengthening is very low. So, we get the end of heads at 75-70 abv.

2. The distillation speed is very high - much higher than I have in my practice. So, again, the reflux with high speed is very low - we get a lot of congeners that lower the spirit content. Again, if the distillation speed at heads stage is high (15-30 minutes total, according to Whisky: Technology, Production and Marketing ed. I. Russell) we "loose" a lot of good spirit with heads and lower the middle cut. In this case the heads appear in a new made spirit in significant quantity. But maybe this is not a problem, because they will evaporate during cask maturation.

One more thing. I suppose that the middle cut usually is about 25-30% from low-wines volume. If we collect middle cut in the range 68-63 abv - this will be much less than 25% and the good spirit yield will be awfully low.

My reasoning may be faulty. Can You explain Your vision of this question?

Thanks in advance.

With great respect, Dmitry.

The distillers cutting below 70abv probably look for more robust oily peaty style, not floral fruity. As you point out, it might be a way to compensate the relatively fast distilling speed and/or low reflux. The heads fraction is recycled to the next batch anyway so the spirit loss is not important.

DeleteGreat stuff, glad to see you writing again!

ReplyDelete"According to Valaer in 1940 there was a legal maximum of one pint of liquid caramel per gallon of whisky permitted by the British Customs and Excise Regulations (0.15% or about 1.5 g/l)." I think there might have been a transcription error, as a pint per gallon is 12.5% (16 oz / 128 oz) which seems a bit loony.

True. Certainly not pint of caramel per gallon, although that is what mr Valaer wrote;) Pint per barrel adds up with the 0.15% nicely, so I changed that. Thanks.

DeleteThanks for this.

ReplyDeleteThe study by Savchuk is really intriguing: Despite the fact that bourbon is aged in a much warmer climate, the older Scotches have a much higher ester count. Why is this? Would the higher temperatures of Kentucky not compensate for their shorter aging time and cause a bit of catch-up chemistry wise?

Probably due to distillation regimes (pot still/column still). Scottish pot still distillation allows (and creates) more esters into the new make. Also more higher alcohols and probably acids, too. And alcohol+acid=>ester. Not that much of a maturation thing in the first place.

Deletehttp://whiskyscience.blogspot.fi/2011/03/pot-still-distillation.html

http://whiskyscience.blogspot.fi/2013/08/history-of-column-still.html

To reply very late, I was under the impression that distillation simply concentrated alcohol and acids which then gradually reacted into esters with time, as opposed to the bulk of esterification being during distillation.

DeleteThe heat (and probably copper) accelerates the ester formation. How much, I don't know, would be great to see some numbers (not too hard to do, looking at you Heriot-Watt). You are probably right about the bulk happening in the cask.

DeleteI would not presume i know enough so i can enlighten you already! Much learning to be Done before i can do that ;) im planning a little experiment myself for the relationship between ABV and wood interaction speeds :)

DeleteThis is an interesting discussion to have, Teemu.

DeleteAnother confusing wrench to throw in is that most Bourbon is made using sour-mash method. This would make it very high in volatile acidity (specifically lactic + acetic). Again this would mean the conditions for esters forming are more ideal, both because of the low pH in both the boiler and columns, and also because of the amount of ester precursors is very high for the same reason.

Teemu, a LOT of esters are created in the still especially under reflux. Look into Arroyo's papers on Jamaican rum. They are stunning.

DeleteHave a bit of Rum Fire or Wray Overproof for an ester bomb.

I have toyed with this myself by adding raw lactic, butyric, and propionic acid directly to the still and the results are promising. The smells before though aren't so pleasing.

Good post.

ReplyDeleteWow, updated

ReplyDeleteLove this site! Makes learning about wine fun. Thanks for sharing!

ReplyDeleteWery good article!!!

ReplyDeleteThank you for article. Assumptions about the nature of Jerez and Montilla-Moriles casks abound. To think the lauded 19th century and early to mid 20th century single malts were often aged in pajarete barrels. Pajarete and PX are kin to drinking liquid raisins. Both seem to pass on a certain residual barrel sweetness to single malts. I know cellulose contributes, but I still taste an inherent sweetness diff from cellulose. Maybe I pick up on the nuances bcs I am experienced with the full gamut of sherry. Either way, seems hypocritical for the whisky industry to not admit how revered malts of yesteryear were aged in "sweetened barrels" (PX or pajarete) not "dry wood" barrels. Would like your input.

ReplyDeletenice writing

ReplyDeleteThis is an AMAZING post. I learned so much. Please continue posting wow!

ReplyDeleteTeemu I am whisky drinker, collector and host tastings of my own. I am desperately trying to find hard science regarding what happens when we pour the whisky into a glass.

ReplyDeleteI am trying to (in scientific terms) describe the effects on flavor

1) when whisky is exposed to oxygen; if there is any oxidation that occurs

2) what happens when alcohol evaporates; does that change anything in the composition or flavor

But I am unable to find any information on these matters. Could you point me in the right direction and/or would you have any articles on this matter?

I'm just about to prepare a series of 15 lectures on flavour of alcoholic beverages...Two lectures will be devoted to whisky...This blog is a Treasure Island of Information!!!

ReplyDeleteVery well researched article - fascinating.

ReplyDeleteI have been a huge fan of you blog for years and refer to it a lot as part of my work. I know you stopped writing a few years ago, but did you ever consider getting this published? I would love to own a hard copy.

ReplyDelete